The launch is the spectacular start of a satellite’s long, and hopefully, productive life. But too little attention is paid to its end. With on-board propulsion systems capable of only giving satellites a small nudge, they can take years to pass through lower orbits before burning up in the atmosphere or potentially hitting the ground. In turn, this not only increases the risk to other satellites but pushes up costs for the operators. One solution is the D-Orbit Decommissioning Device D3, which not only removes a satellite quickly and safely from orbit but prolongs its useful life.

Back in 1908, when the Model T Ford was just about to take the motor industry mainstream, the utility of the windshield wiper in reducing risks of collision on the road was not a strong enough selling point to integrate the blades into newer car models. By 1916, as the need for better safety became more apparent, wipers had become a standard feature on all cars, dramatically improving visibility and allowing drivers to roam farther distances without fearing bad weather conditions.

Today, there is such a heavy reliance on space technology that our daily lives would drastically change should space activities suffer any setbacks. But like the automobile industry in its early stages, space activity is evolving at an increasing rate with little or no regard to preserving a safe space environment, and this may hinder its exploitation for future missions.

Space debris poses a risk in two major ways. First, it represents a navigation hazard for operational satellites, since a piece of debris colliding with a satellite could damage it or worse, as happened in 2009 when a defunct Russian satellite, Cosmos, destroyed an operational Iridium satellite. Today, satellite operators sacrifice propellant — and therefore the satellite’s life and potential revenues — to perform collision-avoidance manoeuvres. Second, it poses a major hazard for people on Earth. According to NASA, in 2014 alone one hundred tons of junk fell back to Earth, and on average one junk object falls from space every day. It is almost impossible to accurately forecast where it will impact.

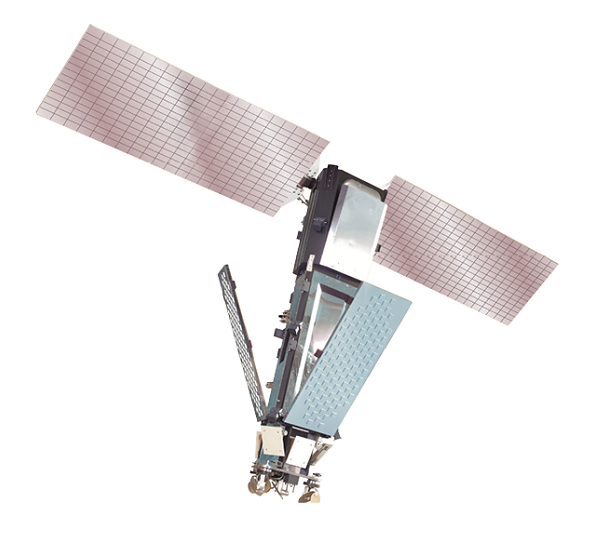

Declared inoperative in 2012, Envisat will take up to 150 years to descend back into the Earth’s atmosphere

The costs to consider for a space operator are increasing and could potentially impact a viable commercial business model. As recently reported by Euroconsult, in the next eight years $255 billion will be spent on manufacturing and launching 1,400 satellites, thus increasing fivefold the number of companies actively involved in the space industry.

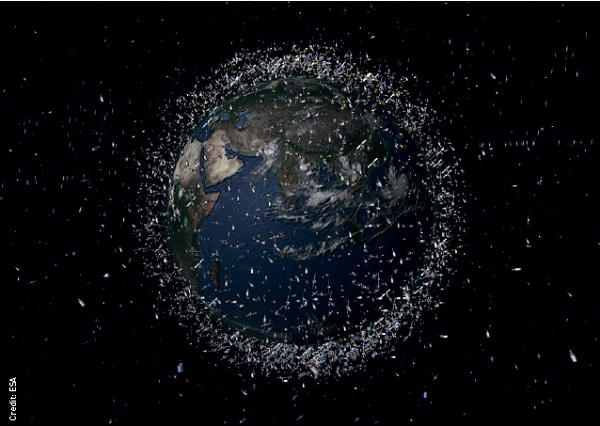

A 2008 illustration depicting debris objects, not shown to actual size, cluttering Low Earth Orbit

A 2008 illustration depicting debris objects, not shown to actual size, cluttering Low Earth Orbit

What’s more, the industry is continuously evolving. Current trends such as the launch of mega constellations and CubeSats can change the entire industry in a matter of years, making any prediction uncertain and introduce new challenges for space debris mitigation. Consider an operator who wants to launch a 1,000-satellite fleet in low Earth orbit with a 10% annual turn-around. The current decommissioning procedure consists in lowering the perigee to about 550km to increase drag and bring the satellite down. Even if compliant with current international guidelines, such behaviour will lead decommissioned satellites to cross for decades through the most densely populated Low Earth Orbit, where the International Space Station is located. Twenty-five years from the first round of decommissioning, there will be some 2,500 spent satellites drifting at various altitudes. This would bring enormous costs to bear for the operator, as it would be liable for any damage its defunct satellites may cause to other operational satellites.

Growing costs

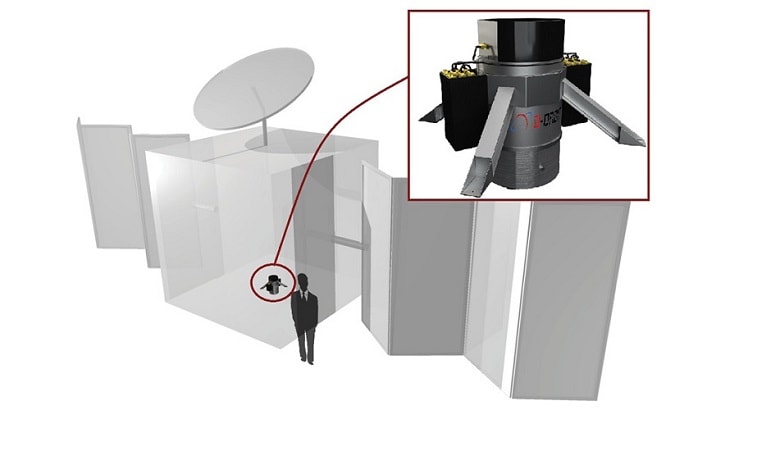

The D-Orbit Decommissioning Device D3 uses solid rocket propulsion to quickly deorbit or re-orbit a satellite

The D-Orbit Decommissioning Device D3 uses solid rocket propulsion to quickly deorbit or re-orbit a satellite

The irony is that these costs tend to grow exponentially with the number of satellites, leaving operators to face a growing erosion of their revenues and making their business unsustainable. Direct costs such as propellant consumption for collision avoidance manoeuvres, downtime during manoeuvres, and end-of-life decommissioning have a big impact on the cost of orbital slot occupation and insurance premiums.

A 2009 ESA simulation shows how crowded Geostationary Earth Orbit would be in 2112 if space debris is not dealt with more effectively

A 2009 ESA simulation shows how crowded Geostationary Earth Orbit would be in 2112 if space debris is not dealt with more effectively

Similar challenges not only affect LEO and large constellations of satellites, but disrupt the business-as-usual scenarios, including GEO and MEO satellites. As space gets more crowded, it is important to be able to clear occupied slots to make way for replacement satellites. This is particularly important in the case of major satellite failure or the impossibility of controlling the satellite from the ground.

The European Space Agency’s Envisat, launched on April 2002 and declared inoperative in 2012 due to an unidentified failure, will take up to 150 years to descend back into the Earth’s atmosphere. Each year this €2.3 billion-worth LEO satellite keeps orbiting uncontrolled, it increases the risk of collision with other objects. For each operational satellite expected to pass within about 200m of Envisat, it will require an extensive team of engineers to calculate precise collision avoidance manoeuvres.

It is very hard for a gauging system to accurately calculate the residual propellant. The margin of error is often higher than 15%

These factors have an impact on satellite design. To avoid redesigning, debris mitigation countermeasures would have to take into account projections for orbital debris concentration in the next 20 years, making satellites heavier and more expensive. In turn, this will lead to an immediate increase in launch costs. The slightest variation during the decommissioning phase can greatly affect the chances of success for the re-entry manoeuvre.

Debris mitigation and avoidance regulations are steadily becoming more restrictive. So far, all of the most exploited regions of orbital space are protected by regulations. Best practices formulated by the IADC inter-agency committee are being implemented at the national level, in new licensing, in satellite manufacturing, and in insurance contracts. In some cases, national legislation implements additional regulations for debris prevention.

The France Space Operation Act requires all national and international operators active on French territory to decommission all LEO satellites orbiting within 2000km at the end of their operational lives. This will involve making the satellite re-enter the atmosphere in a controlled way independently from the casualty risk criteria which is highlighted in several other international standards (for example, ISO 24113, IADC Mitigation Guidelines, European Code of Conduct).

Solving the debris dilemma

Existing solutions ranging from passive deorbiting mechanisms to on-board propulsion systems are only capable of reducing the deorbiting time; they still leave the satellite to drift uncontrolled throughout its descent. These solutions are subject to a high failure rate, and do not offer solutions that are increasingly being required by international space debris mitigation guidelines. Decommissioning is achingly expensive in terms of station-keeping fuel budget and launch mass. Propulsion systems are required to match at least 90% reliability at end-of-life in order to avoid losing control after component malfunction.

Currently, it is very hard for a propellant gauging system to accurately calculate the on-board residual propellant. The margin of error is often higher than 15%. This uncertainty increases operating risks considerably and may hinder, if not eliminate, the chances of successful re-entry at end-of-mission. Due to this uncertainty, the operator faces the challenge of decommissioning a satellite that may have remaining fuel, which could have been used to extend its operational life and subsequent revenues. D-Orbit’s Decommissioning Device D3 is an independent and autonomous system based on solid rocket propulsion. It’s capable of quickly and safely disposing of a satellite at its end-of-life in a controlled manner, freeing up the orbital slot for a replacement, even in the case of satellite failure. With a mass that is only a fraction of the entire satellite, the decommissioning device provides the necessary acceleration to effectively complete a disposal manoeuvre without involving the spacecraft’s propulsive system and ensuring a reliability of 99.9%. Systems like these can increase a satellite’s operational life for up to six months, and reduce the costs of post-mission disposal, especially for large satellite constellations.

At the moment it is not possible to recuperate objects in space, so a dedicated system must be integrated before launch. D3 is currently the only solution completely focused on removing all types of satellites in a controlled way, with an independent decommissioning system dedicated to space debris mitigation. By performing a fast, direct re-entry or re-orbiting manoeuver, the device will help preserve the space environment and decrease costs for operators.

Simplifying the end

The end-of-mission phase is part of the mission, and perhaps the most demanding part of a satellite’s lifespan. On-board propulsion systems are not optimized to include end-of-mission manoeuvre: they are primarily designed to perform small attitude correction manoeuvres and not the highly demanding manoeuvres required post-mission. Since on-board propulsion systems only deliver small impulses in the order of magnitude of 1 Newton, the decommissioning manoeuvre can take a long time - up to 25 years - with additional operational, monitoring and liability costs. Moreover, because of the low thrust, it is unable to perform a direct re-entry, which in many cases is required by international regulations and national laws.

One of the Iridium satellites was destroyed in 2009 when it was hit by another defunct satellite

One of the Iridium satellites was destroyed in 2009 when it was hit by another defunct satellite

A satellite equipped with an independent dedicated decommissioning device, autonomous and specifically designed for this purpose, will no longer suffer from propellant gauging issues because the operator can deplete all the remaining fuel while still being able to remove the satellite at the end-of-mission. This reduces uncertainties and risks, and ultimately extends the satellite’s lifetime. The additional revenues would in turn cover the cost of the device and the extra weight present at launch.

Then there is passivation. Satellites are required by international regulations to permanently deplete or in some way make safe all forms of stored energy — both propulsive and electrical — in order to avoid possible explosions or break-ups in orbit after the end-of-mission. This passivation procedure is relatively complicated, and can result in substantial cost in terms of the complexity of the satellite systems and on-ground operations. If the satellite is disposed of by direct re-entry, passivation is not required. This leads to simpler end-of-life operations and less complex satellite system design.

Finally, a dedicated and independent decommissioning device increases significantly the chances of disposing of a satellite. In fact, the device can perform its removal task even if the satellite is experiencing a major failure that prevents it being controlled from the ground. This has great value in different situations. In the case of geostationary orbit, where narrow slots are assigned to operators, a satellite has to be removed in order to make way for the newer generation.

In the case of large constellations in low and medium Earth orbit, a dead satellite drifting along can jeopardize the functioning of the entire constellation. Finally, in the case of orbits like those for navigation satellites, it is important to keep them clean to guarantee the long-term operability of politically and strategically important constellations.

In the last century, automobile design and performance has evolved beyond the imaginable, progressing towards efficient technology that maximizes safety and minimizes environmental impact without impacting performance. A spacecraft’s features must take safety into consideration to decrease operational risks. In the near future, decommissioning systems will be compulsory by law. To roam further, our visibility must be clear of debris that may hinder future exploration, especially when exploring space.