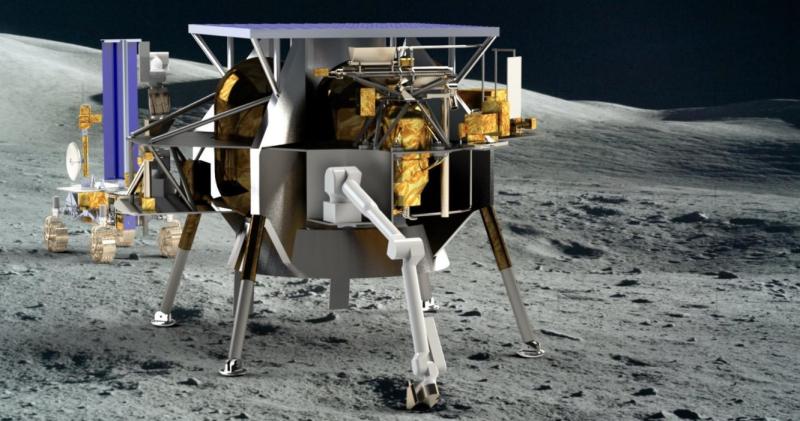

Space Applications Services has signed a contract with ESA to deliver a reactor that will produce oxygen from lunar regolith for the agency’s up and coming in-situ resource utilisation (ISRU) demonstration mission in 2025.

ISRU involves the extraction and processing of local resources into useful products, and for the Moon, the primary source of material is the lunar regolith.

Regolith contains oxygen and water, two key elements used in life support systems and as fuel for power and propulsion systems when mixed with hydrogen.

Aiming to free up these chemicals from the lunar soil and help provide a sustainable presence on the Moon is Belgium-based Space Applications Services, who announced this week that they plan on using a technique that has been used successfully on Earth for the past 30 years.

To produce oxygen from lunar soil, the firm said it will use the FFC process, an extraction method also known as the FCC Cambridge process after its Cambridge inventors, George Chen, Derek Fray and Thomas Farthing, but with a lunar twist.

It uses electrolysis – a technique that uses direct electric current to drive an otherwise non-spontaneous chemical reaction – to separate pure metal from ore, or in this case will liberate oxygen and leave behind metal that could be used in manufacturing applications.

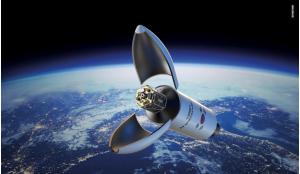

“Today spacecraft must carry all the oxygen they need, for propulsion or life support, from Earth for the entire mission. Enabling spacecraft to “fill up” in space with locally sourced resources, such as oxygen, will play a key role in the exploration of the solar system over the next decades. The ability to extract oxygen from the lunar surface will enable the sustainability of these exploration efforts. The ISRU Demonstration Mission will show for the first time an end-to-end extraction process in a manner representative of a scaled production,” say Space Applications Services in a statement on their website.

Along with the FCC process, Space Applications Services are also looking at producing oxygen via a method known as the Hydrogen Reduction of ilmenite.

Often proposed as a technique for producing water on the Moon, the process involves separating ilmenite – a compound which contains iron, titanium and oxygen (FeTiO3) – from lunar soil, crushing it to a fine powder and then heating it in an enclosed reaction vessel in the presence of hydrogen gas.

The steam produced in the reaction is then condensed and split to produce oxygen and recover the hydrogen.

Although the contract is to develop and deliver a set of 3 reactors Space Applications Systems says it aims to establish a commercially viable lunar plant delivering oxygen.

ESA’s call out for new partnerships to produce drinkable water or breathable oxygen on the Moon by 2025 was issued a few years ago. At the time, the agency said it would finance the best proposals with awards worth up to EUR 500 000.