25 April 2018

New Skyrora launch vehicle focused on UK lift-off!

25 April 2018

New Skyrora launch vehicle focused on UK lift-off!

...thrust at sea level will be capable of producing 30 kiloNewtons. The launch vehicle is also capitalising on advanced manufacturing techniques, including 3D printing to build its rocket components - a technique that has the advantages of cutting costs...

24 February 2021

Orbex commissions industrial 3D printer for rocket engines

24 February 2021

Orbex commissions industrial 3D printer for rocket engines

...imaging-based inspection of printed components. To accommodate the new machinery, Orbex is expanding its factory floor space by an additional 1,000 square metres. The 3D printing system will print rocket parts using a custom blend of metals including...

May 2022

Design architecture for 3D printing a lunar habitat

May 2022

Design architecture for 3D printing a lunar habitat

... 17th century when Dr John Wilkins first proposed the idea of colonising it. Today, with the development of additive manufacturing (AM), widely known as 3D printing, the concept of cost-effective lunar colonisation could soon become a reality. Here...

January 2018

Maximising the economic opportunities of deep space

January 2018

Maximising the economic opportunities of deep space

... appears to be another promising area for deep space investment. Space manufacturing has been pioneered by the additive manufacturing demonstrated in microgravity on the International Space Station (ISS) by NASA partner, Made in Space. What...

October 2024

Lunar construction with regolith and robots

October 2024

Lunar construction with regolith and robots

... content by three percent reflects the alkali-enriched nature of TUBS-M basalt. Although the discrete and additive manufacturing methods each have their advantages, it is considered important to consider a hybrid approach TUBS-T generally matches the...

October 2015

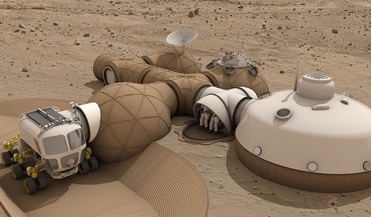

How to 3D-print a habitat on Mars

October 2015

How to 3D-print a habitat on Mars

... developed and tested here on Earth, but this is also a latter part of the NASA Centennial Challenge. The additive manufacturing movement has shown that changing the way you approach fabrication can open up new possibilities. That...