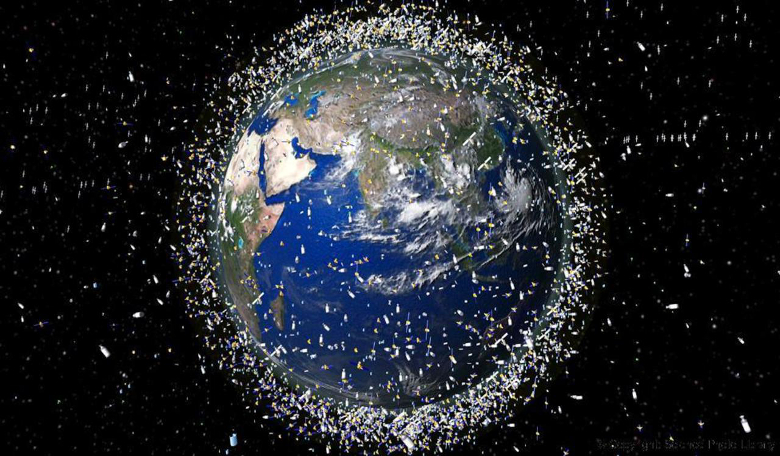

With a growing population of satellites competing for space around Earth’s orbit and with the possibility of mega-constellations adding hundreds if not thousands more satellites to the seemingly already saturated skies, the European Space Agency is launching a Clean Space initiative, tasked with safeguarding terrestrial and space environments from a surge in orbital debris.

“European space suppliers will potentially be manufacturing a large percentage of these satellites, representing a market value of billions of euros,” says Luisa Innocenti, who heads the initiative. “We want European industry to be able to benefit from this market growth while still respecting international space debris mitigation regulations, to keep these key orbits safely usable into the future.

The programme, appropriately named CleanSat will, with the aid of leading European satellite manufacturers and subsystem and equipment manufacturers, help to overcome problems such as how to safely de-orbit end-of-life satellites in a reliable manner without a high impact in mass or cost. Getting a satellite to perform a controlled splashdown into an empty stretch of ocean is actually more expensive than it appears, because as much as four times the fuel than is currently carried aboard is needed to set it on the right course. Consequently a much bigger and more expensive satellite, or even a larger class of launcher is often then required.

When satellites do re-enter the atmosphere, CleanSat’s aim is to ensure that as much hardware as possible burns up, without threatening anyone on the ground. “Satellite reentry is not a single event but rather a process,” explains Tiago Soares of CleanSat. “From observations, we see the main body break apart typically at 70–80 km altitude, after which the insides are scattered. The kind of objects that can survive down to the surface are propellant tanks made from materials with high melting points, such as titanium or stainless steel, along with dense items such as optical instruments and large mechanisms.”

Something that Texans Steve and Verona Gutowski are familiar with when they were woken by the impact of what looked like a “dead rhinoceros” just 50 m from their farmhouse 20 years ago. It turned out to be a 250 kg fuel tank from a rocket stage.

ESA therefore want to ensure that future components conform to something known as D4D or ‘Design for Demise,’ whereby satellite structures and hardware parts burn-up completely on reentry into the atmosphere. Making propellant tanks out of new aluminium alloys for example, could be one way to achieve this.

“However, even redesigned parts will not melt if they are not exposed to the searing heat early enough. This shows the need to adopt an overall approach to D4D, such as opening up the satellite body as early as possible during reentry,” added Soares.

D4D is only one of the avenues being investigated within the CleanSat programme and a further 28 building block technologies have already been looked at. Those that warrant the highest priority will be presented to ESA’s Council at Ministerial Level later this year in December.