ESA channels around eight per cent of its budget into direct technology research and development, an activity mandated in the agency’s founding convention. ESA’s Directorate of Technical and Quality Management runs a suite of technology programmes covering various technical maturity levels and domains. The Directorate’s goal is to ensure enabling technologies become available at the point when upcoming ESA and European missions needs them - one definition of innovation being ‘the right technology at the right time’.

As well as enabling new varieties of missions, technology development also maintains and expands Europe’s general industrial state-of-the-art, boosting the competitiveness of the European space sector in global markets. Compared to other spacefaring nations, Europe finds itself in a unique position, with a space industry that more than pays for itself.

Compared to other spacefaring nations, Europe finds itself in a unique position, with a space industry that more than pays for itself

ESA itself, and European institutional space activities in general, would be economically unviable except for the continued vitality of the wider European space industry - especially in the satellite telecommunications market. Europe’s competitors, by contrast, receive significantly higher shares of institutional support, including effective military subsidies.

Europe’s position is a fragile one, however, reliant on the wider performance of the telecom sector and connected markets. And Europe faces competition both in terms of technology and costs: some competitors can field an order of magnitude higher R&D budgets, others are able to harness nearly unlimited quantities of engineers. We must stay smarter when we cannot be cheaper: Europe must dedicate more resources for R&D in order to guarantee a truly level playing field in the global marketplace.

A changing space industry

Meanwhile, the space industry itself is changing fast. Within Europe, sales to commercial and export customers are close to parity with sales to public sector governmental entities. As the space sector matures, space products and services are becoming seamlessly integrated into the wider economy, finding new markets and classes of customers in the process. Space systems are becoming an essential part of the overall communication system, together with ground networks and ubiquitous smart devices, from smartphones to the emerging ‘internet of things’.

In the decade ahead, a new generation of launchers will enter service, reducing the cost of access to space, at the same time as large satellite constellations look set to dominate applications. These trends are likely to influence space engineering in turn: the old emphasis on maximised capabilities and ‘gold-plated’ reliability of a single large satellite will give way to reducing overall life cycle costs and reliability of supply and schedule on a batch production basis.

The way manufacturing occurs is itself evolving rapidly: the design and production process is becoming digitalised, shortening the production cycle to bring designers, manufacturers and customers closer together. Digitalisation moves the real effort from the manufacturing phase to design: digital models can be concurrently engineered by different specialists simultaneously then put through detailed multi-physics simulations to ensure they are ready for production through 3D printing and other smart, automated production processes to optimise resource usage and quality.

Meanwhile, the general pace of technical progress continues to increase, with a faster turnaround across every technology sector. The lifespan of a given technology - within which it is first investigated for space, then qualified, then made operational and then finally made obsolete with the onset of another superior technology - is continuously shrinking. This trend is set to strengthen with the increasing influence of faster-moving commercial markets, and the growing adoption of ‘commercial off-the-shelf’ parts for space missions, as a way of drawing maximum benefit from terrestrial technological progress.

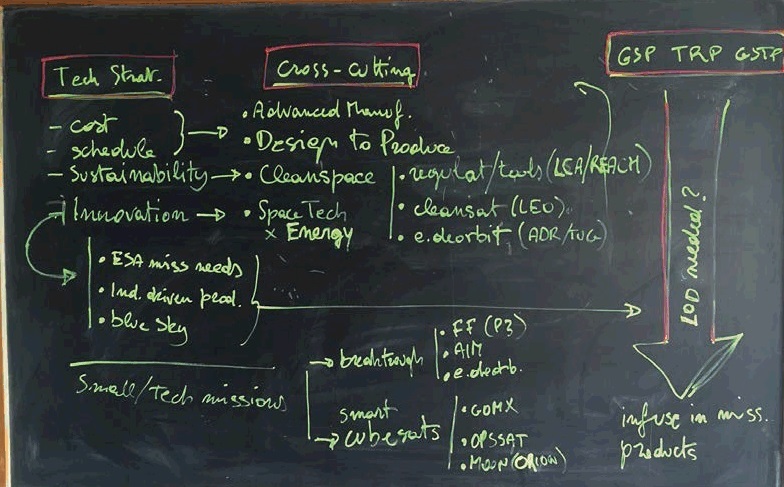

ESA R&D strategy pillars.

ESA R&D strategy pillars.

Our R&D strategy pillars

ESA missions have succeeded - and the wider European space industry has prospered - because of our proven ability to anticipate technology and mission trends and come up with effective solutions. And as the shape of the future changes, the way we prepare for it must change as well.

In preparation for ESA’s Council at Ministerial Level at the end of 2016, the Directorate of Technical and Quality Management is setting forth its future R&D strategy. This new strategy is built on four supporting pillars: cost, schedule, sustainability and game-changing innovation.

The space industry is today at an inflection point: while maximising mission performance was once the governing engineering principle, the priority now to ensure ongoing competitiveness is cost reduction.

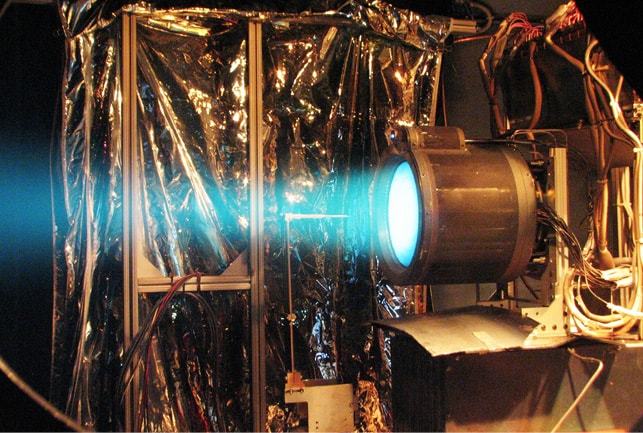

The blue exhaust trail of an ion thruster during a test firing. A quartet of these highly efficient T6 thrusters is being installed on ESA’s BepiColombo spacecraft to Mercury.

The blue exhaust trail of an ion thruster during a test firing. A quartet of these highly efficient T6 thrusters is being installed on ESA’s BepiColombo spacecraft to Mercury.

What does this mean in practice? Rather than improving the cost-effectiveness of any individual development phase, the real goal is to minimise the overall life cycle cost (LCC): improving how we deliver, operate and finally dispose of space systems will give a competitive advantage over time.

For a typical ESA mission, the cost of building a satellite represents up to 60-70 per cent of the total LCC, with the rest covered by the so-called ‘common costs’: launch, flight operations and data ground segment. Up to 20 per cent of this satellite cost may be spent on the assembly integration and test process - although ESA’s current European Ground Systems Common Core programme aims to reduce this number by developing a common infrastructure to support space systems monitoring and control in pre- and post-launch phases for all mission types. Procuring components and materials make up much of the rest of the satellite cost - with plenty of scope for cost reduction.

A prototype 3D-printed antenna being put to the test in ESA’s Compact Antenna Test Facility.

A prototype 3D-printed antenna being put to the test in ESA’s Compact Antenna Test Facility.

Schedule is, in turn a significant driver of project cost. Delays lead to more than simply monetary losses: time-to-market is also a key factor in competitiveness. ESA’s flagship Basic Technology Research Programme (see below) has already been transitioned to a shorter two-year planning cycle, allowing more rapid reaction to new ideas and needs, while its General Support Technology Programme has been redesigned to be more responsive to industrial needs.

Our Directorate continues to target increasing the speed of bidding and processing of new R&D contracts. A new cross-cutting initiative called ‘Design to Produce’ (see box) will seek to spin-in the latest industrial processes.

A new approach will also be adopted for ESA requirements and qualification processes: when a potential commercial customer is ready to buy a product at a lower performance or qualification level than usual for products qualified for ESA missions, this will now be supported - with the potential to ‘upgrade’ later for different mission scenarios, allowing the more rapid take-up of emerging technologies.

If the space industry is going to remain viable into the future, sustainability is non-negotiable. We share the same planet as everyone else and cannot escape far-reaching environmental regulations such as the European Commission’s Registration, Evaluation, Authorisation and Restriction of Chemical Substances (REACH), which seeks to limit industry’s use of chemical substances that may be hazardous to human health or the environment.

Around four per cent of our database of industrial materials made use of by the space industry will be impacted by REACH in the short term, a figure likely to double in the mid-term and rise to as high as 20 per cent in the long term.

It is essential to manage the resulting risk of obsolescence - where certain commonly employed materials and processes are no longer available for use in space industry supply lines. Waivers can be applied for, but will not be indefinite in nature. It is far better to react proactively and look for cleaner alternatives. This work is being undertaken by ESA’s Clean Space cross-cutting initiative (see Cross-cutting Initiatives box), aiming to safeguard both the terrestrial and orbital environments. Clean Space is also tackling space debris mitigation and remediation, to ensure highly-trafficked orbits remain feasible to employ on a safe and affordable basis.

We also need to strengthen our R&D programmes, the seamless chain of innovation that has served ESA and Europe well. Initial investigations are carried out through ESA’s General Studies Programme, assessing novel mission concepts, or the Basic Technology Research Programme (TRP) - the ideas factory of the agency, that converts initial ‘blue-sky’ concepts into working prototypes.

Higher level technology development is supported through the optional General Support Technology Programme (GSTP), maturing new technologies for space and the marketplace and honing industrial competitiveness. Finally, the circled is closed by bringing space technologies back to Earth, through ESA’s Technology Transfer Programme, to spread the benefits of innovation to wider sectors of industry and society. Fresh emphasis is being placed on the investigation of potentially disruptive and game-changing concepts, enhancing open innovation mechanisms to bring in non-space and academic partners, and boosting in-orbit demonstration opportunities.

Technology demonstration missions

By far the best way to establish the market-readiness of novel European space technologies and products is to actually demonstrate them in space. Responding to feedback from industry and member states, the Directorate is expanding opportunities for early in-orbit demonstration of promising technologies through the General Support Technology Programme, re-oriented around a ‘Develop - Make - Fly’ model.

Digitalisation moves the real effort from the manufacturing phase to design

The basic model comes from ESA’s Proba family of technology-demonstration mini-satellites, the first of which launched in 2001. The Proba NEXT mission is currently in development, a follow-up to the Proba-3 precision formation flying mission, among other technology-demonstration missions (see below).

The ESA–RAL Advanced Manufacturing Laboratory on Harwell Campus in the UK assesses new material processes, joining techniques and 3D printing technologies for application in space

The ESA–RAL Advanced Manufacturing Laboratory on Harwell Campus in the UK assesses new material processes, joining techniques and 3D printing technologies for application in space

Flight demonstrators can also be placed as hosted payloads on a variety of carriers - including suborbital rockets, launchers, satellites and the International Space Station (ISS) - with all onboard resources required - such as mass, volume, power and data interfaces. The Directorate is also using CubeSat nanosatellites for in-orbit demonstration. Standardised dimensions increase their number of launch opportunities, while their high degree of modularity and extensive use of commercial off the shelf subsystems mean they can be readied for flight on a much more rapid basis compared to traditional satellites.

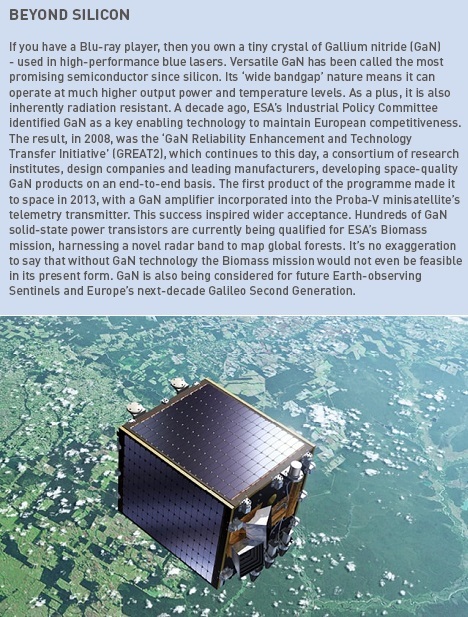

Proba family

Each minisatellite in the ‘Project for Onboard Autonomy’ series - all smaller than a cubic metre in volume - is crammed with as many technology demonstration payloads as possible. Earth-observing Proba-1 in 2001 demonstrated the first hyperspectral imager and the first lithium-ion batteries in orbit, in 2009 the Sun-watching Proba-2 flew the first LEON2-FT microprocessor and first Active Pixel Sensor startracker, and in 2013 Proba-V took on the global land monitoring task previously undertaken by France’s Spot satellites, while also performing the first detection of aircraft ADS-B signals from orbit and testing Europe’s first transmitter amplifier based on gallium nitride. Proba-3, set for launch in 2019, is a double-satellite mission dedicated to precise formation flying.

e.Deorbit

ESA’s e.Deorbit, for launch in 2023, will be the world’s first large-scale space debris removal mission, to capture and deorbit an entire ESA-owned derelict satellite. It will require extremely sophisticated guidance, navigation and control to synchronise motion and then capture its target, guided in turn by advanced image processing and data assimilation. The technologies in question will also serve as the basis of future in-orbit servicing or refuelling services for satellites.

Asteroid Impact Mission

Novel technology is what does the most to create new applications and services, opening up new markets to deliver jobs and growth

ESA’s 2020 Asteroid Impact Mission will demonstrate a host of enabling technologies for future deep space missions, including advanced onboard autonomy, laser communications, inter-satellite links and low-gravity operations, while exploring the Didymos binary asteroid system and monitoring the impact of NASA’s DART spacecraft with the smaller of the two bodies.

CubeSats

ESA’s first technology-testing CubeSat was GomX-3, deployed from the ISS in 2015, which performed worldwide aircraft tracking with a miniaturised ADS-B receiver. Follow-ups include the reentry-focused KARMAN, atmosphere-sounding Picasso and the radiometer-hosting SIMBA.

Technology - a wise investment

Investment in space technology pays for itself. The space sector provides more than 320,000 jobs across Europe, from manufacturing to space operations and downstream services, estimated by the European Commission to be worth about €52 billion to our economy, from an annual public investment of €8 billion (combining ESA, EC and national space agency spending). And novel technology is what does the most to create new applications and services, opening up new markets to deliver jobs and growth.

Proba-V satellite.

Proba-V satellite.

In the end it all comes down to the human element. Technology, as a working definition, is the practical application of knowledge so that something new can be done. To put it another way, technology is the single attribute that defines us, Homo sapiens, as a species: our ability to make and use new tools. Most of the human body is unremarkable when compared to other animals: it is the tool-making ability of our brains and hands that took us from the African savannah to the Sea of Tranquillity on the Moon. Behind ESA’s often remarkable technological achievements, human curiosity and foresight remain the driving forces.

Franco Ongaro graduated as a Doctor of Aeronautical Engineering from the University Politecnico of Milan. He joined ESA in 1987 working at ESTEC in the Netherlands as Head of the Columbus Payload Interfaces Unit from 1988. He was shortlisted as candidate in the European astronaut selection of 1991 and took up duty as Director of Technical and Quality Management (D/TEC), and Head of ESTEC in Noordwijk, the Netherlands, on 1 April 2011.