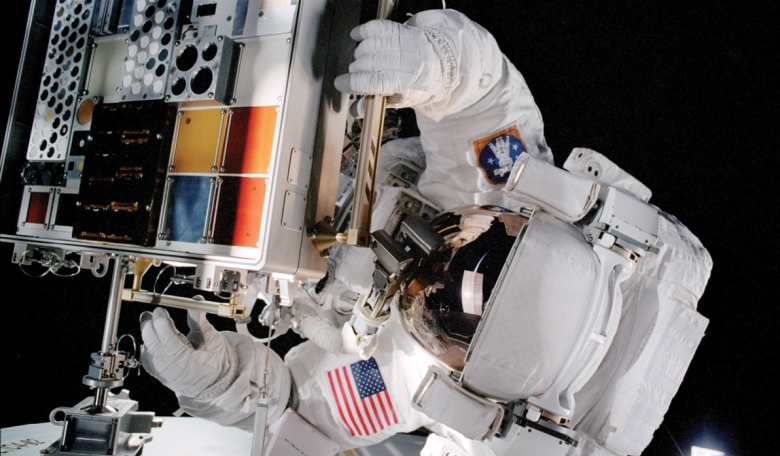

Space missions of all kinds are becoming ever more ambitious in terms of frequency, distance and complexity. As mission requirements grow and evolve at an increasing rate, Dr Barrie Dunn looks at how the global space industry is pushing the boundaries of materials science and is addressing the need for more qualified materials engineers in the field.

Technology in the space industry is in a constant state of change and materials scientists and engineers are working to overcome the technical difficulties associated with increased launches and extended missions over ever greater distances.

Lightweight and exceptionally strong (high modulus) materials and lubricants with very low-outgassing under vacuum properties are being specially developed for space applications. Special surface treatments are being formulated and processed to be both very hard and adherent to their substrates, to exclude the cold-welding phenomenon where metal sticks to metal due to surface wear and the absence of oxygen to regenerate oxide protection layers.

The materials and processes (M&P) requirements associated with the space industry are highly demanding and a continuous challenge to the engineers involved in reducing the risk of failure. Teams of metallurgists, chemists and electrical and structural engineers work to avoid conventional hardware failures that may cause the loss of function of a spacecraft system or designs that are so costly to build that the project fails on economic grounds.